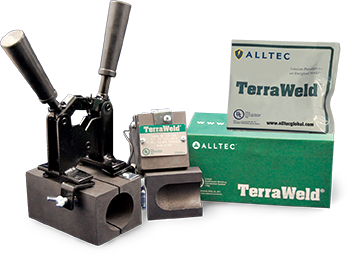

TerraWeld® Exothermic Welding System

TerraWeld® exothermic welding system provides a superior solution via permanent molecular bonding. Exothermic welding is the industry preferred method of making electrical connections due to its inherent molecular level reliability for conductors and grounding points.

- Welding does not require external heat or power source

- Will not loosen or increase in resistance over time

- Superior electrical conductivity than the conductors themselves

- Will not corrode, oxidize, or degrade over time

- Compatible with copper, steel, columbium, bronze, iron, copper-clad steel, stainless steel, Monel, niobium, brass, & silicon bronze.

- Requires no special skills

- Highly portable

- Reduces labor costs

TerraWeld® Applications

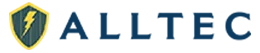

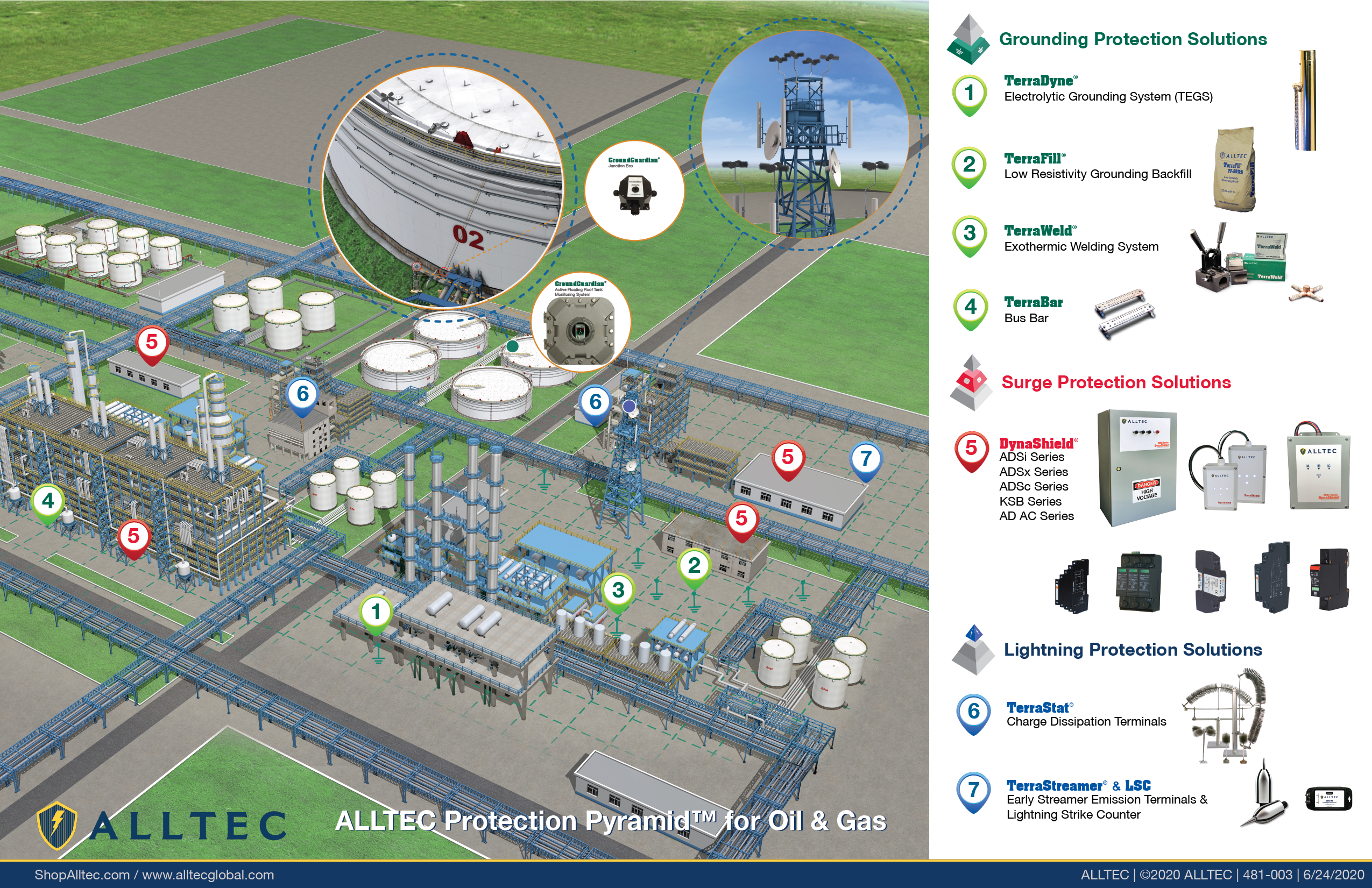

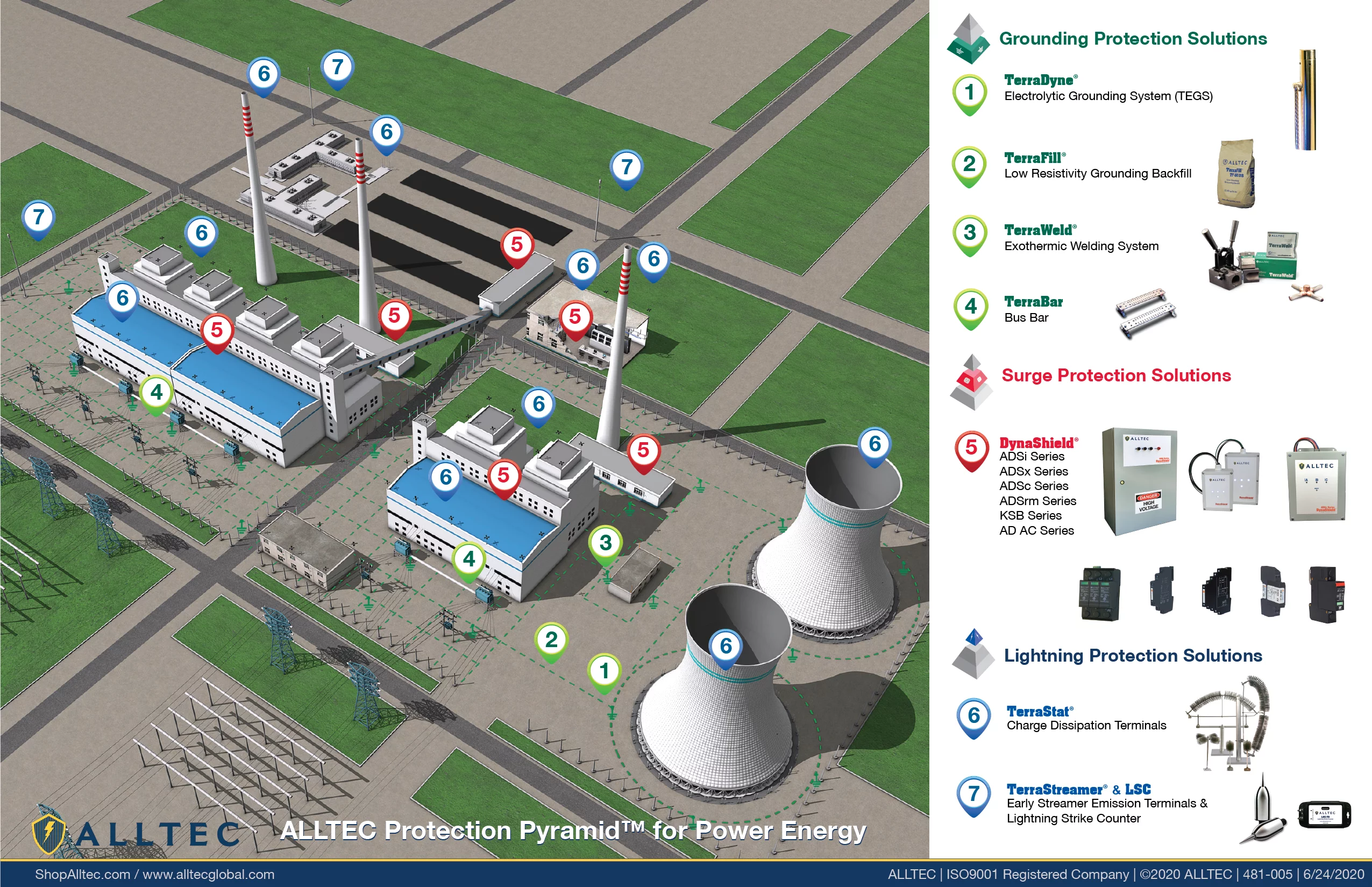

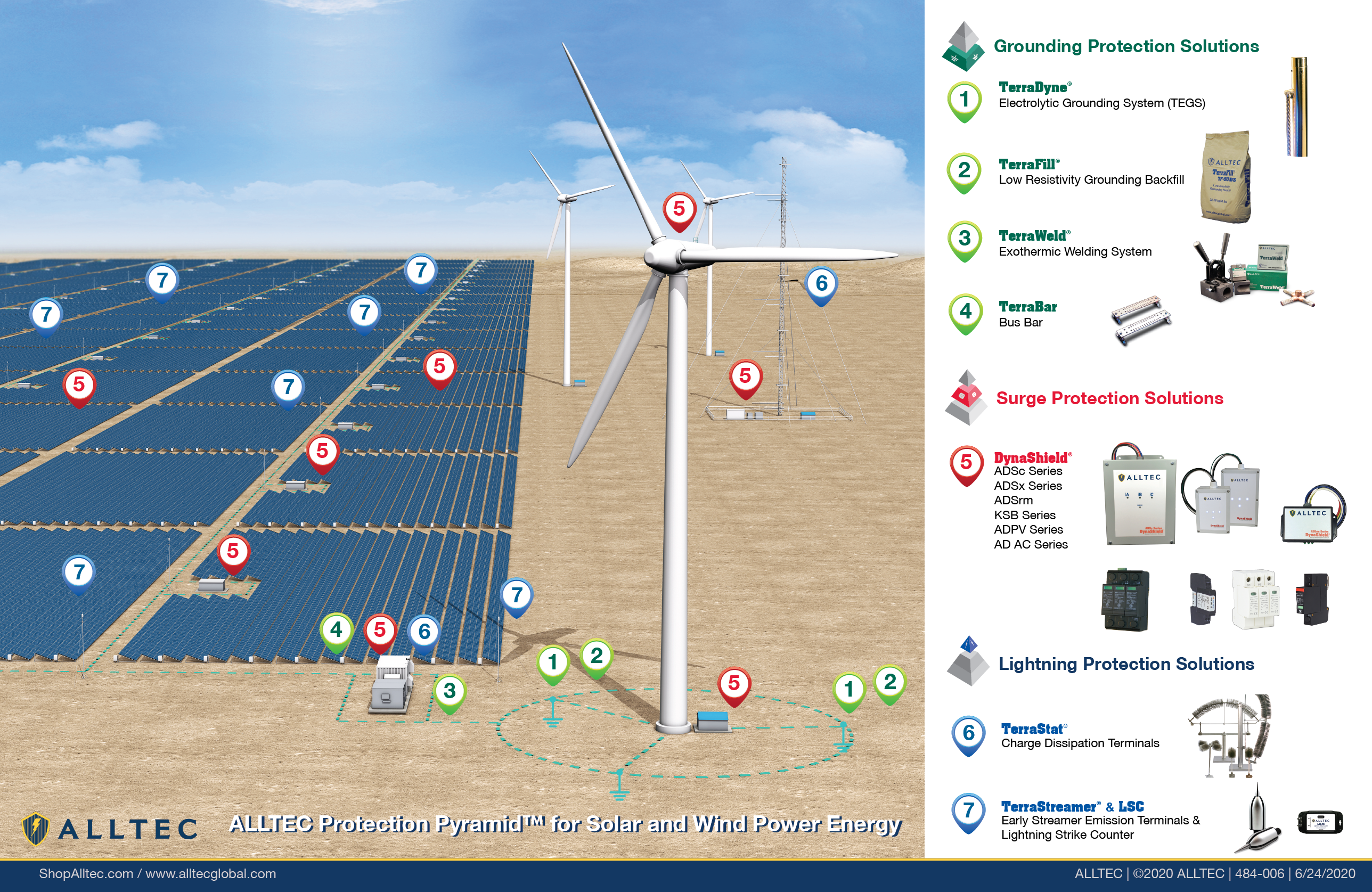

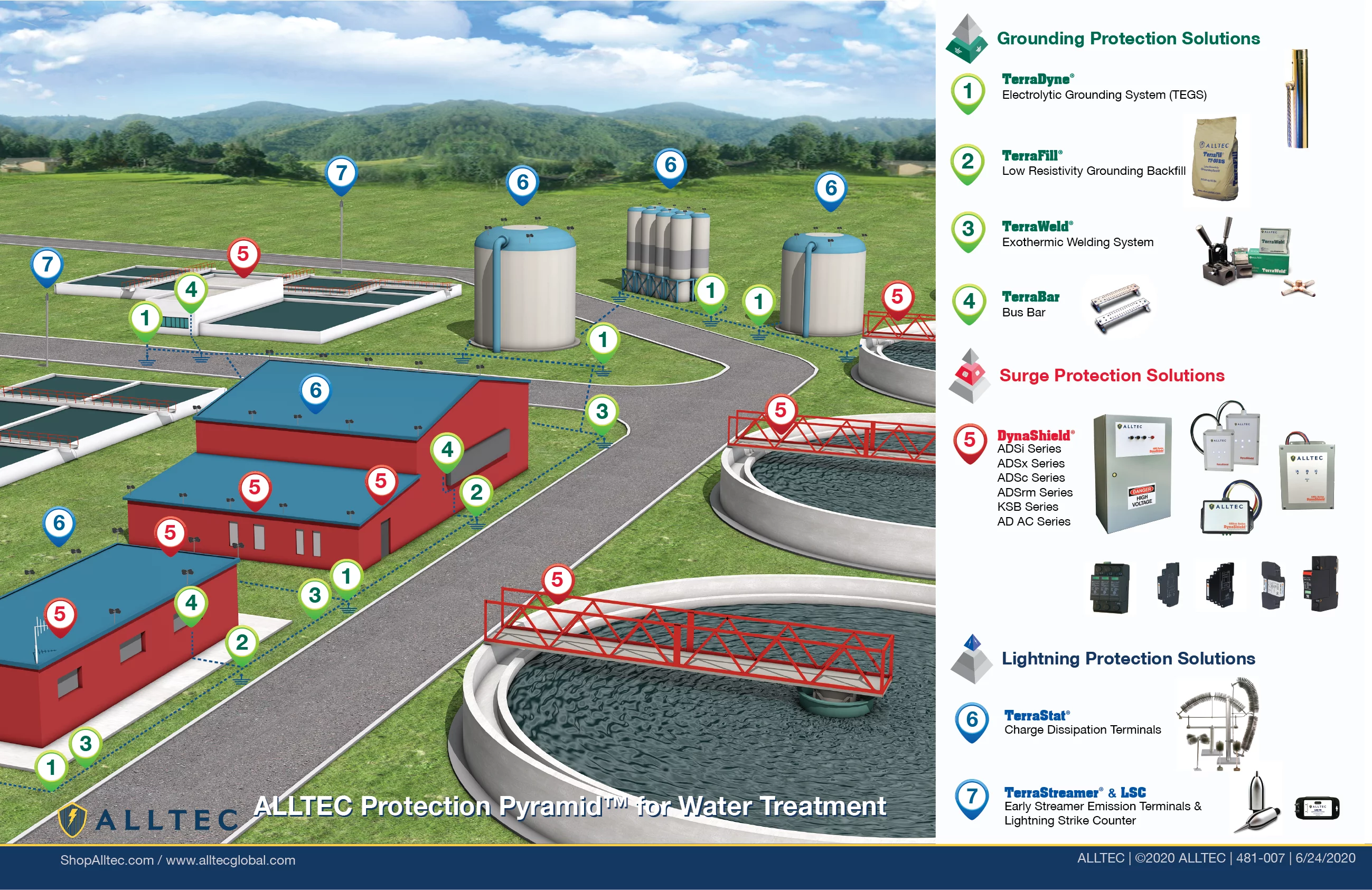

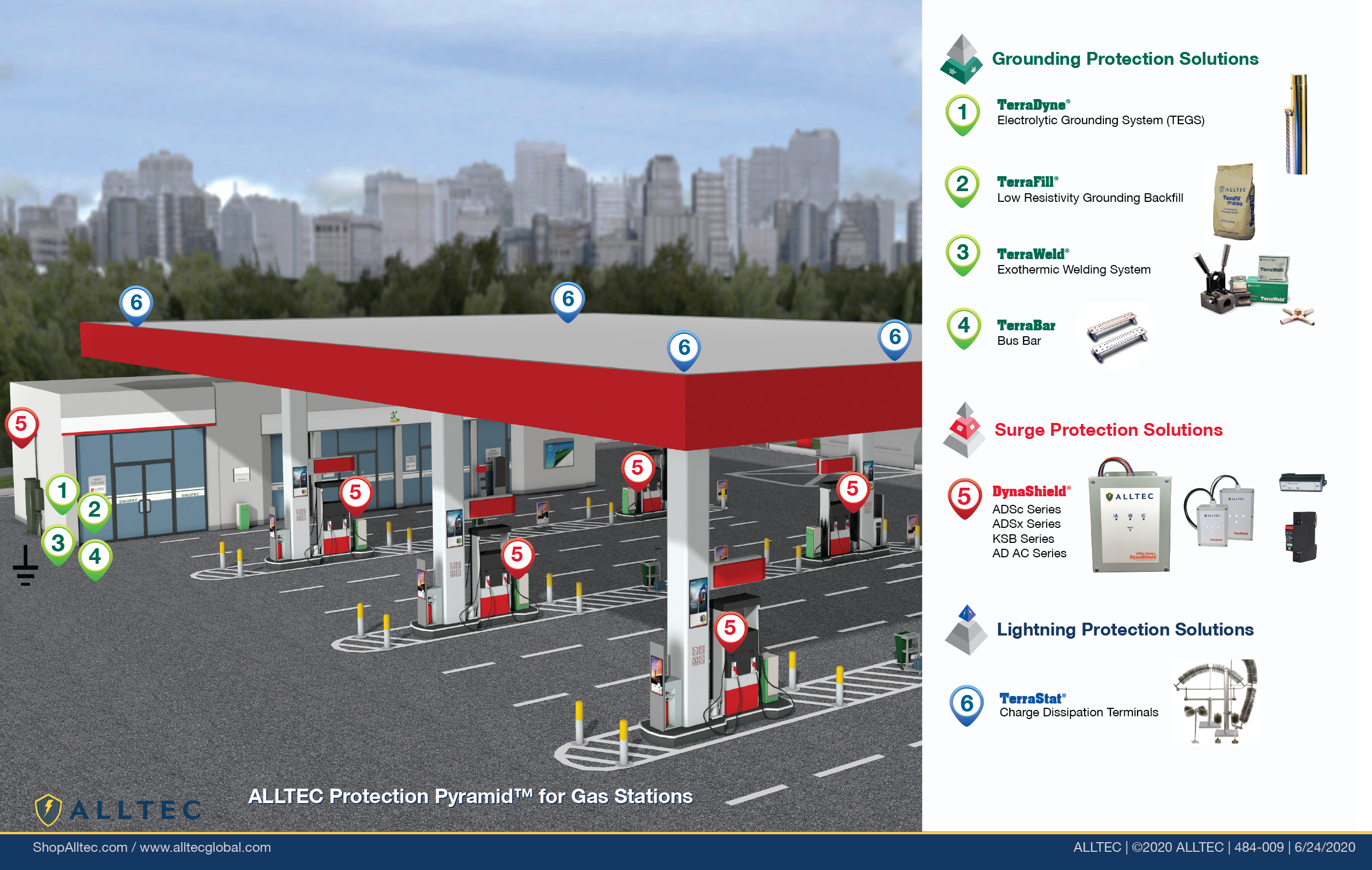

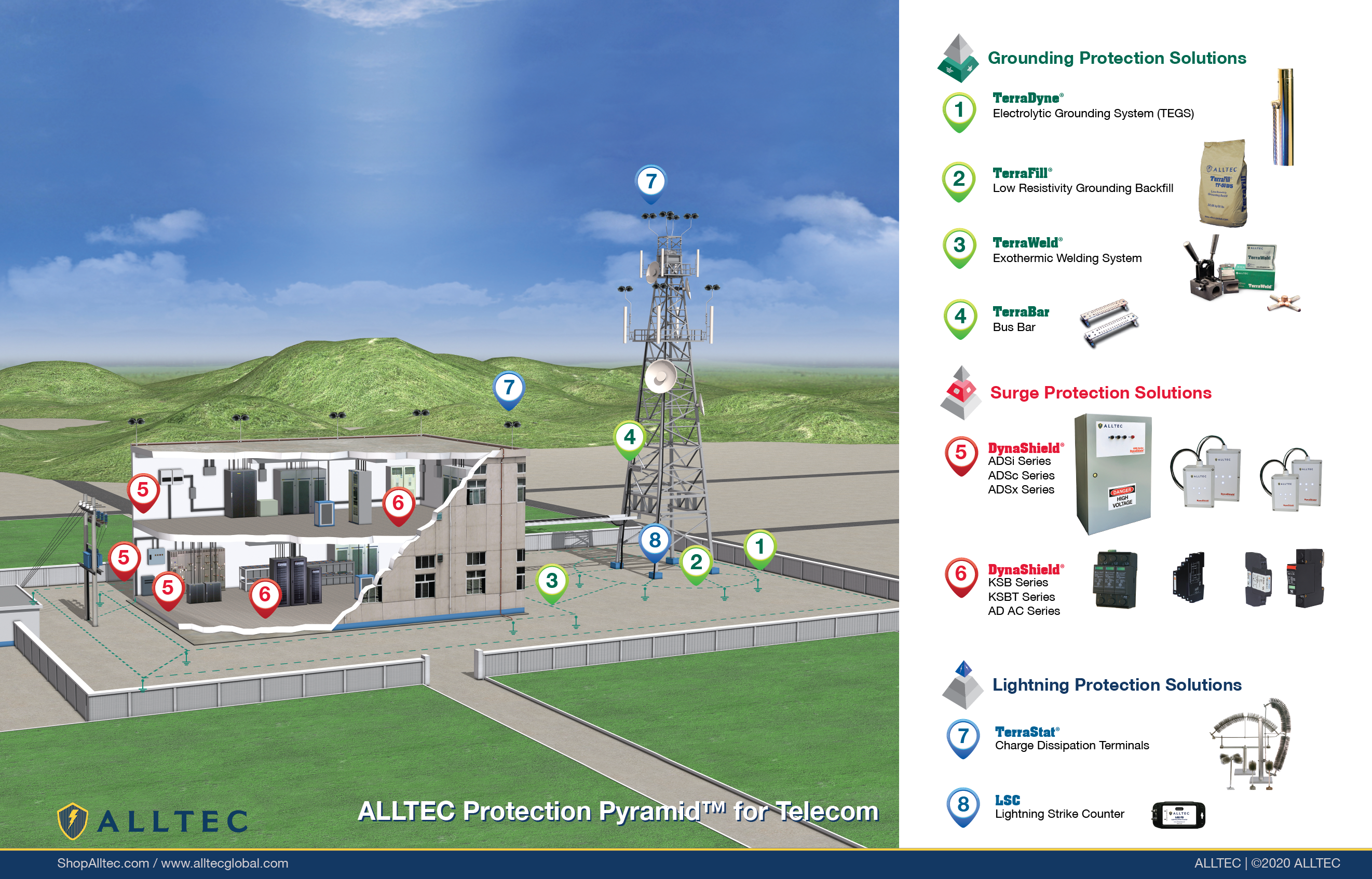

TerraFill® creates a reliable, low resistance electrical connection between the grounding system and the earth. It is manufactured to be compatible with copper grounding systems and standard field application methods. It can be used in connection with grounding grids to minimize step and touch potentials. You can view typical installation locations in the application maps to the right by locating the number 2.

How it Works

The TerraWeld® Exothermic Welding System is a welding process that utilizes an exothermic reation (a chemical reaction that releases energy in the form of very high temperatures and light) to permanently join metal connections. Terraweld® uses a light-weight, clamp-on graphite mold to safely position and contain any weld required. The exothermic reaction creates an intense miniature furnace with temperatures exceeding 2,500 °F, instantly producing molten metal which flows into the weld cavity, filling any available space. After waiting adequate time after the initial process, the mold can be released and the finished connection removed.

Our News

March 1st Price Increase

To our Valued Alltec Customers, Unfortunately, we continue [...]

Alltec is Moving!

We’re Moving to a New Location! [...]