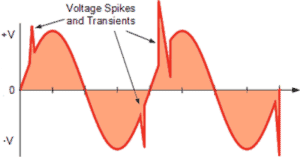

Electrical transients are momentary bursts of energy induced upon power, data, or communication lines. They are characterized by extremely high voltages that drive tremendous amounts of current into an electrical circuit for a few millionths, up to a few thousandths, of a second. Large transients on the power system originating outside of a facility are best initially diverted at the service entrance of a facility. Transients generated within the premises are best diverted by SPDs located close to the internal source of the transients or close to the electronic load equipment if this is not possible. Best results are obtained if both locations are protected.

Electrical transients are momentary bursts of energy induced upon power, data, or communication lines. They are characterized by extremely high voltages that drive tremendous amounts of current into an electrical circuit for a few millionths, up to a few thousandths, of a second. Large transients on the power system originating outside of a facility are best initially diverted at the service entrance of a facility. Transients generated within the premises are best diverted by SPDs located close to the internal source of the transients or close to the electronic load equipment if this is not possible. Best results are obtained if both locations are protected.

Where do transient surges come from?

Surge activity is often assumed to be generated by an outside source. Lightning-induced electrical energy bursts typically come to mind as the primary source of surge activity. However, while lightning induced surges represent the most formidable equipment menace, most surges originate from internal sources within a facility.

A range of equipment creates internal transients: from copiers to coffee makers, vacuum cleaners to variable speed drives, and from fluorescent light ballasts to furnace igniters. Studies have verified that approximately 80% of transient activity at a given facility is internally generated. Copiers and laser printers are notorious transient generators as are heating and air conditioning systems. Any time an inductive load is either powered on or off it generates a low magnitude surge impulse that propagates back through the electrical system. While internally generated transient activity can weaken equipment over time, the threat posed by lightning activity is particularly disconcerting due to its capability of delivering vast amounts of energy into unsuspecting electronic equipment loads.

How vulnerable is my equipment?

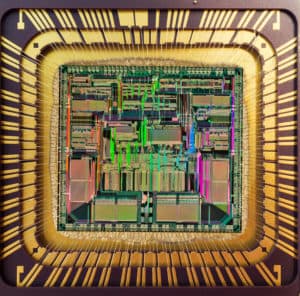

Today’s electronic equipment is particularly vulnerable to the voltage component of the transient energy. That’s because modern computer chips are comprised of millions of active circuits positioned upon a silicon wafer whose surface area measures no more than a square inch. There isn’t a lot of physical space separating the microprocessor’s components. It doesn’t take much of an overvoltage, lightning-induced or otherwise, to damage its components.

Surge suppressors, now more than ever, are required to protect electronic equipment. Transient overvoltage surges measuring as low as a few hundred volts/peak pack enough punch to damage sensitive electronic equipment beyond repair.

The voltage element of a transient surge is received like a slap in the face by modern integrated circuits (ICs), i.e., computer chips. In the same manner that we would feel a rush of pain if someone slapped us across the cheek, the computer chip will suffer in a similar sense albeit metaphorically. And while a series of quickly reoccurring and repeated slaps across our face would result with our feeling intense pain, multiple back to back transient surges occurring in quick succession will cause an otherwise healthy computer chip to fail catastrophically.

It becomes prudent to mitigate the potential damage associated with transients. That task is accomplished with surge protection devices (SPDs). SPDs have a fundamental purpose: to protect critical electronic equipment by diverting intense levels of transient current away from them while limiting the corresponding voltage amplitudes to safe levels. In other words, an SPD serves as electronic shock absorbers that attract transient surge energy and safely soaks it up before it gets to its protected equipment.

An inside look at a microprocessor.

General Electric reported in their in-house magazine, “Current Scene,” the observation of transient surges of several thousand volts regularly occurring on 120 V power circuits within facilities ranging from family homes to large industrial manufacturing plants.

Surge Protection Safety Standards

SPD safety standards have been revised in recent years. Now standards call for testing that stresses the SPD should fail while ensuring that it does so safely. SPD failures typically are caused by temporary overvoltage (TOV) events rather than surge activity. While most surge suppressors have always easily withstood momentary voltage bursts, they could and would fail catastrophically when subjected to a sustained overvoltage high enough to drive them into continuous conduction.

When ANSI/UL 1449 – 2nd edition was revised to include extended abnormal overcurrent test parameters during February 2007, safety testing required SPDs to be subjected to a full gamut of abnormal fault current scenarios. Testing required them to conduct various amounts of fault current until they failed in a safe and orderly fashion. SPD products of yesteryear, without redesign or augmentation, could not meet the new enhanced safety requirements. While ANSI/UL 1449 was revised in September 2009 with the advent of its 3rd edition, the overcurrent testing implemented in its previous iteration remains significant.

A strong argument can be made that SPDs still in service and manufactured before February 2007 – before today’s accepted safety standards adopted more robust testing requirements, are not entirely safe for use. They should be replaced based solely on safety concerns. However, since most SPDs employ suppression components that wear out over time, it is not a bad idea to replace older SPDs as a preventative measure.