Copper ground bars (also known as busbars) are a building block of electrical installations because they provide a common grounding point for multiple electrical circuits.

The purpose of ground bars:

- Safety: They help prevent electrical shock by providing a path for fault currents to safely dissipate into the ground.

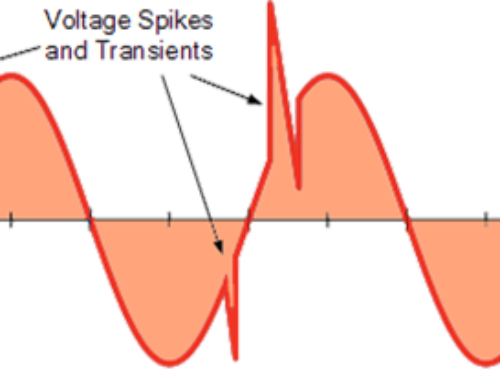

- System Protection: They protect electrical systems and equipment from damage caused by lightning strikes, power surges, and other electrical faults by directing excess current away from equipment.

- Electrical Noise Reduction: They reduce electrical noise and interference in electronic circuits by providing a low-impedance path to ground, which is essential for the proper functioning of sensitive electronic equipment.

- Compliance: They ensure that electrical installations comply with national electrical codes and standards, which require proper grounding and bonding.

Ground bars in Lightning Protection applications:

Ground bars play a crucial role in a lightning protection system as the central grounding point that helps dissipate the immense electrical energy from a lightning strike safely into the ground. Here’s how they fit into the system:

- Connection Point / Path to Ground: When lightning strikes a structure equipped with a lightning protection system, the energy is directed through a network of conductors, down to the ground bar. The ground bar then provides a low-impedance path to the earth, allowing the energy to safely dissipate into the ground.

- Equal Potential Bonding: Ground bars ensure that all components of the lightning protection system, as well as other grounded systems within the structure (such as electrical systems, plumbing, and communication systems), are at the same electrical potential. This helps prevent dangerous voltage differences that can cause arcing and damage.

- Compliance and Inspection: Ground bars are a visible and accessible point for inspecting the integrity of the grounding system. Properly installed ground bars ensure the lightning protection system complies with standards such as the National Fire Protection Association (NFPA) 780 and Underwriters Laboratories (UL) 96A.

Now that you know what they are and how they work, at ALLTEC, we manufacture our own version of ground bars in our factory located in Charlotte, NC USA under the TerraBar® brand. We offer a full line of available hole patterns and sizes along with all the associated mounting hardware and insulators. We keep the raw materials on hand for these, so our turnaround time is lightning fast!

We can also handle custom configurations, just submit a quote request here.

ALLTEC’s engineering and design department, in conjunction with its manufacturing facility, is available to assist in custom designed grounding products to fit any application.

Leave A Comment