ALLTEC Protection Pyramid Surveys — A Three Part Series

If you missed Part I, “Grounding & Bonding,” or Part II, “Surge Protection,”; you may find them by clicking on the linked text.

This last installment of our three-part series relates to the top tier of the Protection Pyramid, lightning protection. The implementation of this capstone tier is required to:

Protect critical facilities, equipment, records, and assets

Provide a safe working environment for personnel

Reduce the risk of downtime and lost revenue

Minimize liability and maintain a competitive posture

Build a disaster resilient enterprise

Grounding, bonding, and surge protection alone is not sufficient to adequately protect a facility. A lightning protection system (LPS) should also be installed and fully integrated into the facility’s inspection and maintenance program. Correctly staged surge protection, proper bonding, and low impedance and low resistance connection between earth and the LPS components is essential.

In the United States alone, lightning detection systems monitor an average of 25 million flashes of lightning from cloud to ground every year. Lightning is reported to cause $4-5 billion in damage annually. Properly designed, installed and maintained lightning protection systems (LPS) are over 98% effective in preventing damage associated with a lightning strike.

Improperly Installed Lightning Protection

An improperly installed, non-compliant lightning protection system is dangerous. Please be sure to hire an experienced lightning protection contractor. Roofers, general contractors, and electricians typically are not qualified to install lightning protection systems according to national safety standards.

Lightning Protection Site Evaluation

As with any survey, the best way to start is with a site review:

Collect information on types of damages experienced or anticipated by the facility and create a prioritized outline of survey requirements.

Study existing lightning protection system “as-built” drawings.

Review site electrical panel layouts, one-line electrical, and riser diagrams for power and data lines entering/exiting the facility

Additionally, before the physical walk-through and inspection, it is useful to obtain, review and retain for possible use in the final report, the following:

Lightning protection specification/standard related to the installation

Site plan & “satellite view” using geographical coordinates

Individual building/structure architectural & mechanical rooftop plans, elevations, and wall sections

While elements of grounding systems and surge protection, as described in previous articles, are part of a lightning protection system survey, the LPS survey should specifically relate to at least one the following standards to have a basis for determining and reporting compliance or noncompliance:

UL 96A “Standard for Installation Requirements for Lightning Protection Systems”

NFPA 780 “Standard for the Installation of Lightning Protection Systems”

LPI-175 “Standard of Practice for the Design-Installation-Inspection of Lightning Protection System”

NF C 17-102 “Protection against Lightning” Early Streamer Emission

Lightning Protection System Inspection

An initial survey will include an inspection of existing air terminals, lightning masts, down conductors, clamps, or ground electrode connections. However, it is important to inspect the lightning protection system after installation. A thorough examination should be made after a lightning discharge, roof repairs, construction, or structural modifications that may affect the lightning protection system. An annual inspection is recommended for:

Air terminals

Bonding connections to metal objects

Conductors

Splicers & connector fittings

Thru-roof connectors

Evaluation of new additions or protruding structural elements or equipment which may be unprotected

Additionally, surge protection devices should be inspected every six months or after a major thunderstorm. Every three years, ground system resistance should be tested per IEEE 81, and the LPS should be tested for continuity.

Changes/repairs that impact the effectiveness of the lightning protection system

Issue created

The surveillance camera, which was installed after the original lightning protection system installation, is unprotected from a lightning strike. An air terminal is required for the camera since the metal arm does not have a metal thickness of greater than 3/16 of an inch. Also the camera arm lacks a bond to the lightning protection system to prevent side flash.

Reference

Per NFPA 780-2014; paragraph 4.6.2.1 The tip of an air terminal shall be not less than 10 in. (254 mm) above the object or area it is to protect. Paragraph 4.6.1.4 . Metal parts, of a structure that are exposed to direct lightning flashes and that have a metal thickness of 3/16 in. (4.8 mm) or greater shall only require connection to the lightning protection system in accordance with Section 4.8.

Recommendation

Installation of a 5/8 x 18” aluminum air terminal with a 2” aluminum horizontal air terminal clamp base. The air terminal and base shall be installed at the outer portion of the camera arm. A “dead-end” single run conductor shall be spliced to the main run conductor located on the parapet coping with a two-bolt parallel cable splicer.

Reference

NFPA 780-2014 paragraph 4.9.2 Dead Ends. A “dead ended” main conductor shall be permitted between a single strike termination device or connector fitting and a main conductor run under the following conditions: (2) At a main protected roof level, where the horizontal portion of the dead-end conductor is not more than 8ft (2.4 m) in total length.

Issue Created

Apparently, during a repair, the air terminal was removed from the coping and is being positioned by the stiffness of the aluminum conductor. No adhesive was present to indicate that the base was re-adhered to the coping after the repairs.

Standards Reference

Per NFPA 780-2014 paragraph 4.6.2.2.1 Air terminals shall be secured against overturning or displacement by one of the following methods:

- Attachment to the object to be protected

- Braces that are permanently and rigidly attached to the structure.

Recommendation

Remove all existing adhesive from the bottom of the air terminal base, or replace the air terminal base, and adhere the base with an approved roofing adhesive. Confirm the distance between the adjacent air terminals does not exceed twenty feet (20’-0”).

Issue created

The lightning protection cable routed to the through roof cable connector is creating a “U” pocket increasing impedance on the flow of a stroke charge.

Reference

Per NFPA 780-2014; paragraph 4.9.4.1 Conductors shall maintain a horizontal or downward coursing free from “U” or ”V” (down and up) pockets.

Recommendation

The lightning protection conductor shall be routed from the roof surface to the through roof cable connector at a slope not greater than 3” per foot (3/12).

Reference

NFPA 780-2014; paragraph 4.9.6.1 Conductors shall be permitted to he coursed through air without support for a distance of 3 ft (0.9 m) or less. NFPA 780-2014; paragraph 4.9 Conductors. Main conductors shall interconnect all strike termination devices and shall form two or in or paths from each strike termination device downward, horizontally, or rising at no more than 1/4 slope to connections with grounding electrodes.

This three-part series on the topic of “Alltec Protection Pyramid Surveys” stresses the importance of understanding the interrelationship and interdependence of the three tiers in protecting any facility. Even when suitably designed and installed, continuous inspection and maintenance is required for all systems to function.

- Without proper grounding, neither the surge suppression nor lightning protection will function correctly.

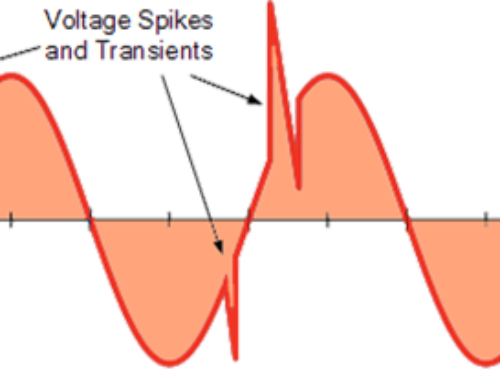

- Without surge suppression, equipment is exposed to the secondary effects of lightning as well as internally generated transient voltages

- Direct strike lightning protection protects the physical structure and its contents.

ALLTEC proposes working with your representatives to evaluate your facilities and investigate all problems and concerns related to lightning protection, surge suppression, and grounding. ALLTEC has the skills, experience, and tools to accomplish this project’s requirement in a timely and professional manner. We look forward to working with you.

If you have an existing or planned facility, be sure to give ALLTEC a call or email.

If you have an existing or planned facility, be sure to give ALLTEC a call or email. We can make sure your operation is the safest possible facility, backed by our team of dedicated risk-mitigation experts. If you have a current or future project that needs grounding/bonding solutions, surge suppression or lightning protection please contact ALLTEC at either 1-828-646-9290 or online-info@alltecglobal.com